News & Fairs

Economical machining of lead-free alloys

Economical machining of lead-free alloys

Carefully optimised geometries and coatings enable a long service life when cutting threads.

The pneumatics and electrical equipment manufacturer Festo produces a wide range of fittings, screws and sleeves at its production plant in St. Ingbert. Due to health risks and the being used for this purpose. At Festo, this resulting legal requirements, material alloys without lead - lead-free alloys - are increasingly mainly concerns aluminium and brass. Currently, for example, banjo bolts for machines and devices in the food industry are being manufactured. These are now made from the lead-free aluminium alloy E754-3 25AA 2033T8.

Highly abrasive

However, lead-free aluminium alloys, comparable to lead-free brass, can only be machined productively and economically with optimised manufacturing processes. During machining - turning, drilling, milling - they have difficulty forming the usual chip shapes. This usually results in irregularly breaking and crumbling chips that are difficult to remove from the workpiece. However, this means that the usual cutting edges of cutting tools wear prematurely or even break out.

Optimised and coated cutting edges

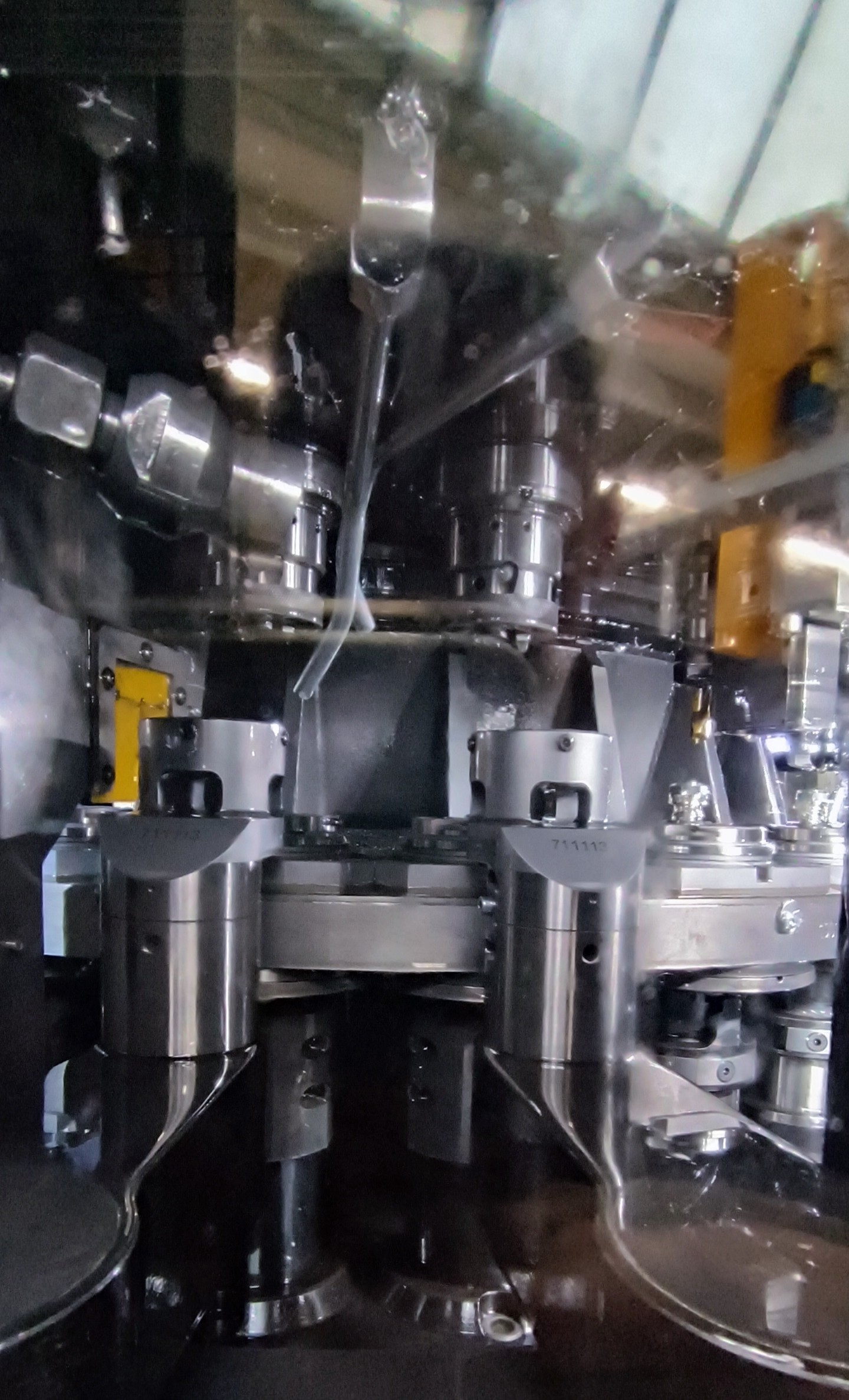

The specialists at Festo use a Piccola rotary transfer machine from the Italian machine manufacturer Gnutti to manufacture the threads of the banjo bolts for valves made from the lead-free aluminium alloy in a highly productive manner. This initially proved to be less reliable. The thread cutting dies previously used wore out too quickly and could not be planned.

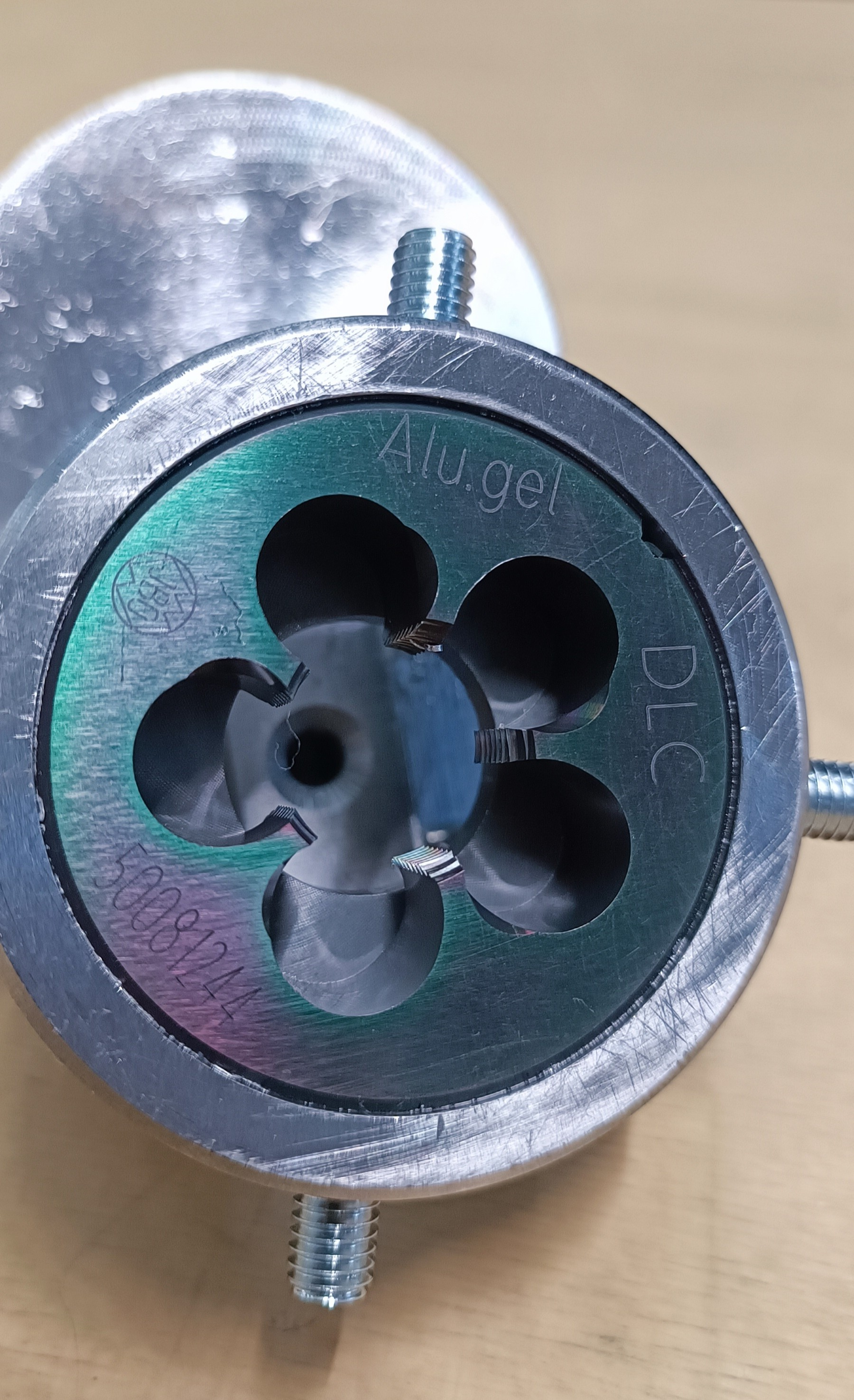

In order to still be able to manufacture economically, the production technicians at Festo needed suitable thread cutting dies with innovative cutting edge geometries and coatings. To this end, they utilised their long-standing collaboration with the tool experts from the manufacturer JBO Johs. Boss GmbH & Co. KG, Albstadt.

Various geometries, cutting values and coatings were and are being tested. HSS cutting dies with cutting geometries specially adapted to aluminium and a Diamond-Like-Carbon (DLC) coating now produce the G 3/8″ threads on the banjo bolts.

Easy cutting with good sliding properties

Easy cutting with good sliding properties. As the tool experts at JBO confirm, the DLC coating on the cutting edges of the thread cutting die ensures that chips slide off much more easily. The hard coating also protects against wear. The rotary transfer machine at Festo produces the threads on the banjo bolts at a speed of 900 1/min, corresponding to a cutting speed of 47 m/min. The now optimised threading tools from JBO achieve a service life of approx. 30,000 threads. This makes them particularly resistant to wear. As the production technicians at Festo in St. Ingbert confirm, they achieve correspondingly long tool lives in order to be able to machine economically. According to internal statements, this is a milestone, as manufacturers of other tools are still struggling with low tool life or reduced cutting values. This circumstance significantly increases the cycle time for all other machining operations and significantly reduces the output.

Energy-efficient and reliable

The HSS thread cutting dies have an aluminium geometry and DLC coating so that they require less torque and offer greater wear protection. This ensures maximum process reliability and efficient production of external threads at Festo. Previously used, non-optimised threading tools required irregularly high torques and often caused individual spindles of the rotary transfer machine to be overloaded. As a result, the latter came to a standstill and the production processes on the rotary transfer machine had to be restarted, which was time-consuming and labour-intensive.

In contrast, the optimised threading tools from JBO now work much better. They only require around 70 to 80 per cent of the drive power or torque of the former thread cutting dies. Downtimes of the work spindles are therefore avoided. This is primarily due to the good sliding properties of the DLC coatings. The optimised threading tools from JBO thus ensure energy-efficient and reliable production of components made from lead-free alloys in large series at Festo.

Picture credits:

©Festo SE & Co. KG, all rights reserved

Sie sind bereits bei unserem Newsletter registriert. Möchten Sie Ihr Abonnement ändern oder kündigen? Klicken Sie hier!

back top

back top