JBO Thread

Milling Cutters

An added value for modern CNC machining

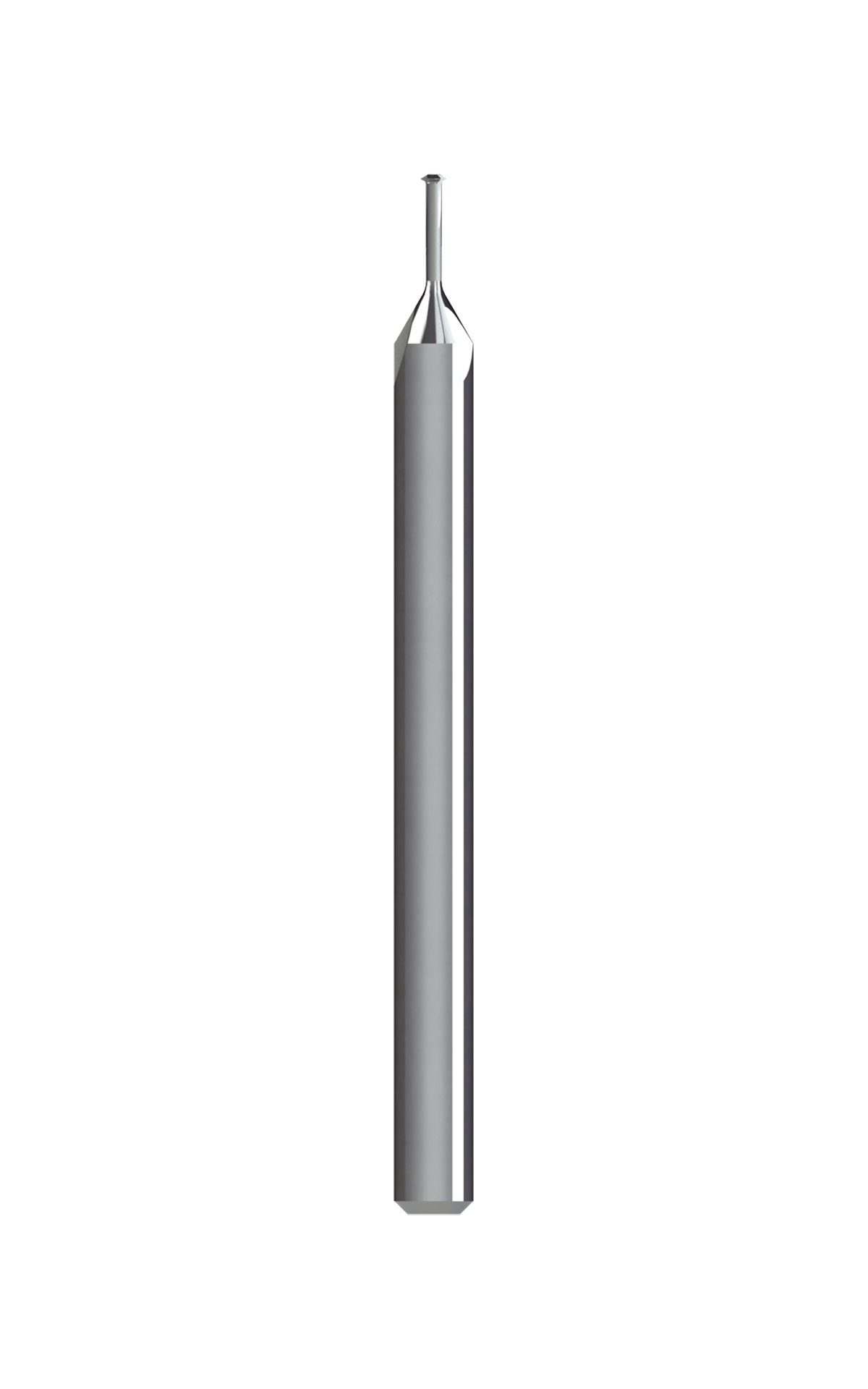

Long time life, shortest processing times and an excellent surface quality - these are just three advantages of our solid carbide thread milling cutters, -wide range thread milling cutters, -drill thread milling cutters and indexable thread milling cutters.

Do you need special thread milling cutters? No problem!

We analyze

your process of machining and work out a cost and quality optimized

solution.

Our product range

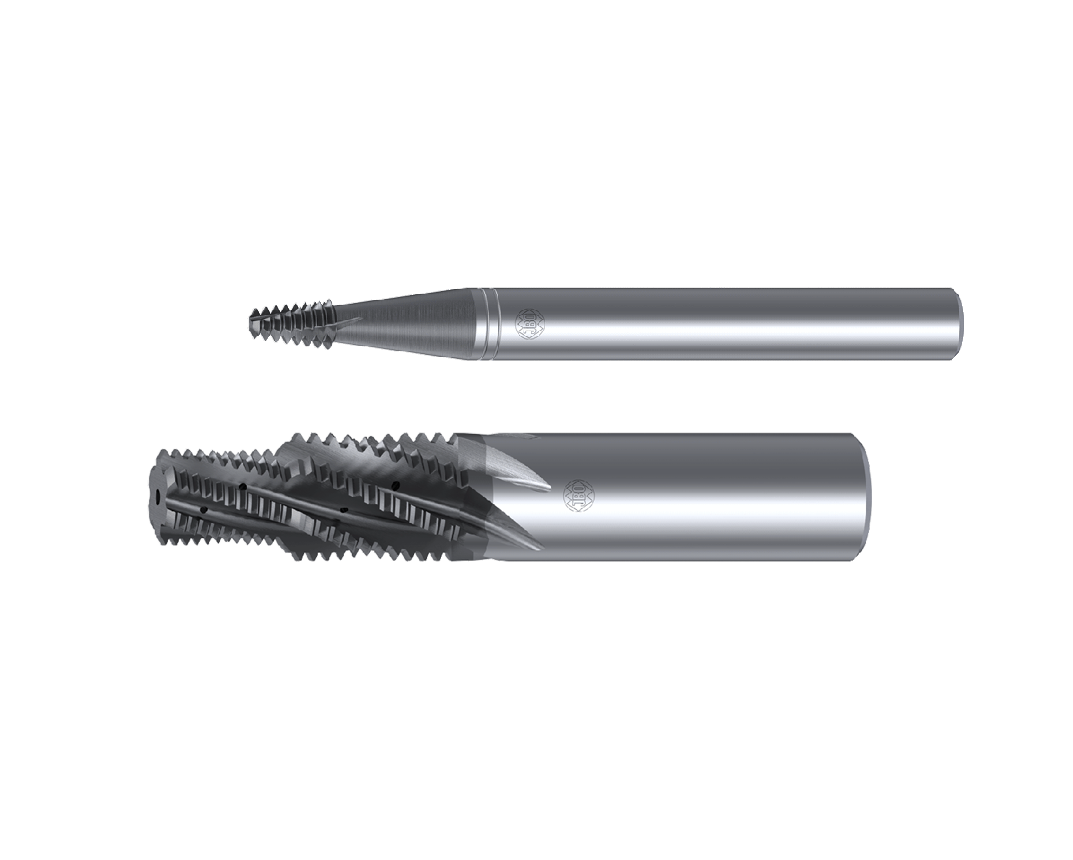

Solid carbide |

Solid carbide |

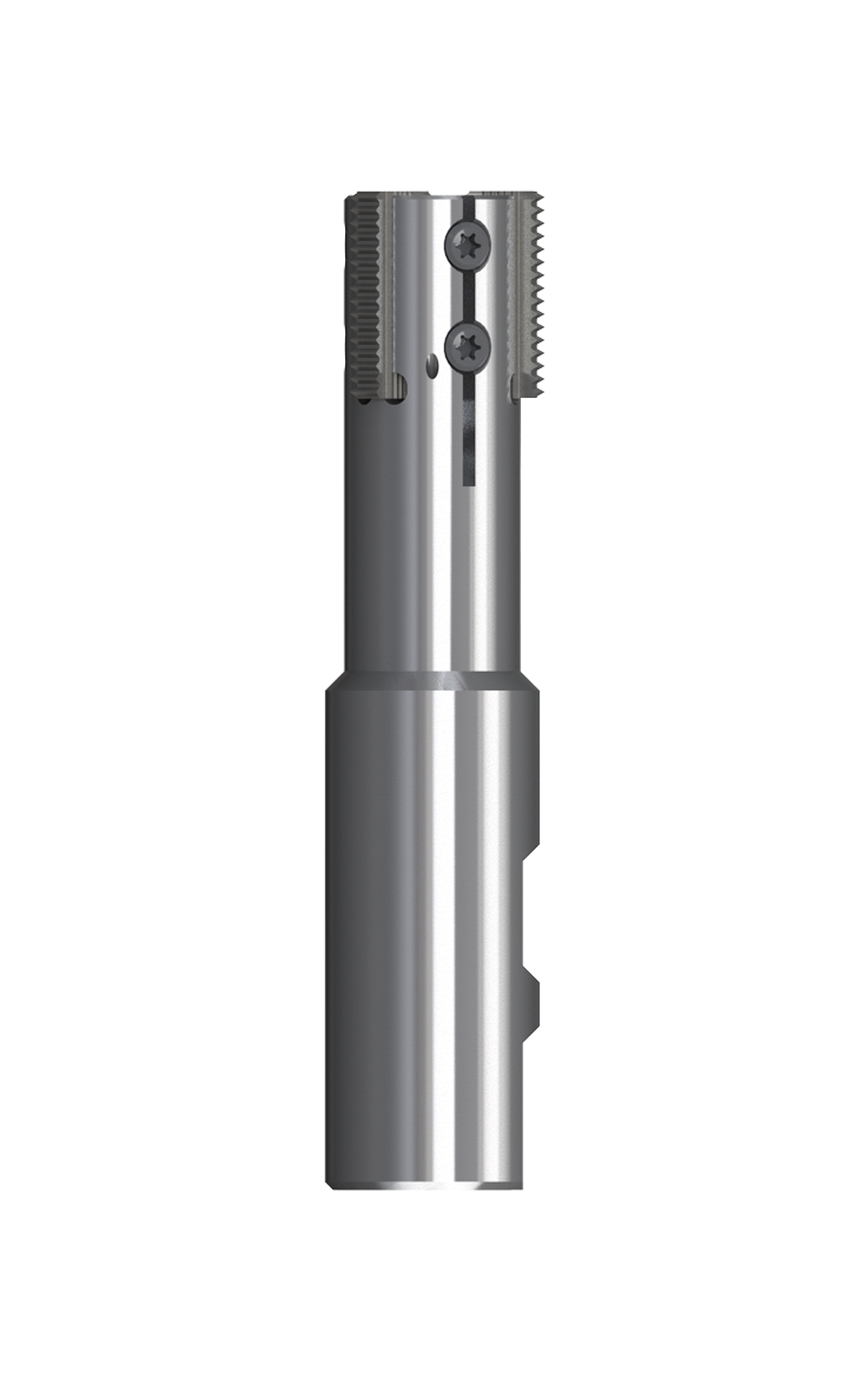

Indexable |

General advantages of thread milling

-

Threads to different tolerance classes can be produced with same cutter

-

Tool breakage does not necessarily entail scrapping of the workpiece

-

Less power needed for cutting internal threads

-

Short machining times due to high cutting speeds

-

Excellent thread surface finish

-

Short chips, hence no chip problems

-

Right and left hand threads can be produced in blind or through holes by the same cutter

-

Low cutting forces enable threads to be cut in thin wall workpieces

-

Cutting speeds and feeds can be matched individually to workpiece material

-

No change of cutter spindle direction of rotation required

-

No special tapping chucks required, standard chucks suffice

-

Threads can be cut to exact depth

-

Threads can be cut down to near bottom of blind holes

-

Start of thread accurately determined by NC programme

Do you need

special tools?

No problem!

We analyse your threading and develop an economic

and high-quality solution, which is exactly adjusted

to your requirements!

JBOtronic -

programming software

To work with thread-milling for our customers

and those who want to be as simple as possible,

we have developed the software JBOtronic.

With JBOtronic the creation of thread milling programmes

for DIN- / Heidenhain-based NC controls conditions

is efficiently possible

JBOtronic supports you with

back top

back top